FINISHED PRODUCT DIVISION

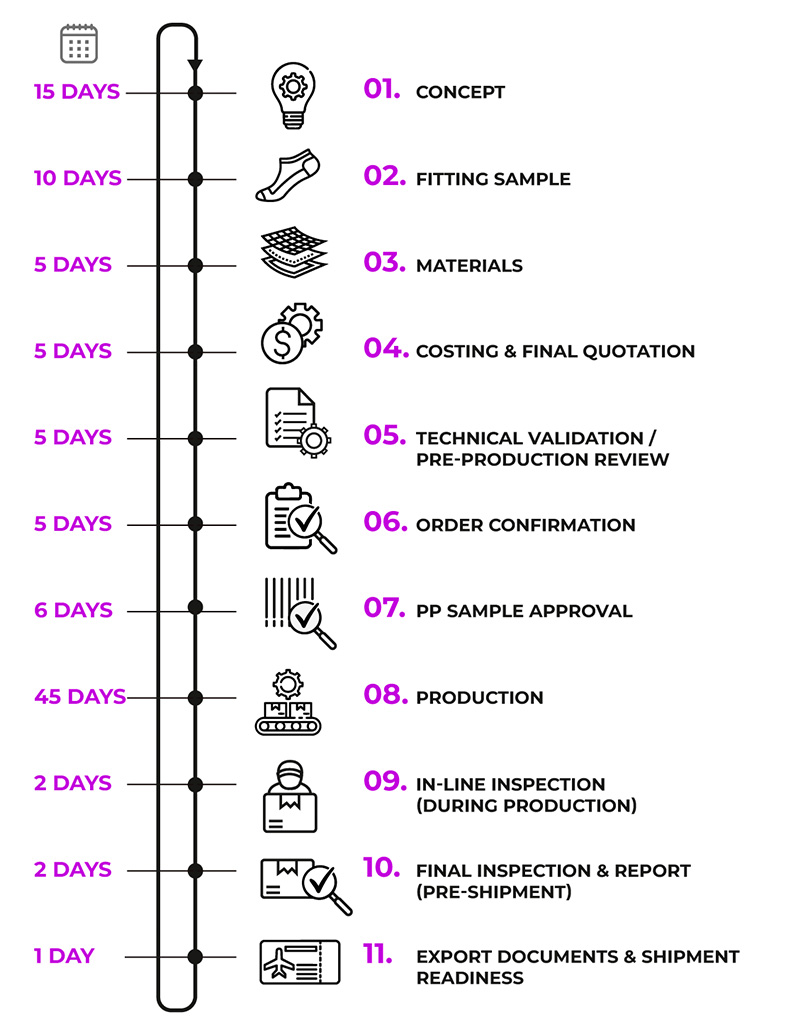

PRODUCT DEVELOPMENT PROCESS

Approximate delivery time 30 days

Our Fabrics and Trims Division specializes in selecting, sourcing, and developing fabrics, trims, and embellishments aligned with each client's creative direction and quality standards. Each material is chosen with purpose, ensuring coherence, durability, and consistency in color and design.

01.

CONCEPT (15 days)

We align the idea, construction method, and fit — transforming creative direction into an action plan.

02.

FITTING SAMPLE (10 days)

First prototype to validate proportions, fit, and structure — design ready for production.

03.

MATERIALS (5 days)

Sourcing and confirmation of fabrics, trims, and components according to brand standards.

04.

FINAL COSTING AND QUOTATION (5 days)

Transparent costing after material and sample approval; basis for order planning.

05.

TECHNICAL VALIDATION / PRE-PRODUCTION REVIEW (5 days)

Validation of tech pack, tolerances, quality standards, labeling, packaging, and tests with the supplier and quality team.

06.

ORDER CONFIRMED (5 days)

We define payment terms, production timelines, packaging specifications, shipping volume, and special requirements. Everything clear before production.

07.

PP SAMPLE APPROVAL (6 days)

Pre-production sample (and color/lab dip approvals, if applicable) formally approved before mass production.

08.

PRODUCTION (45 days)

Start of production under monitoring by the quality team and defined checkpoints.

09.

IN-LINE INSPECTION DURING PRODUCTION (2 days)

In-process quality audit to correct deviations early:

■

In-line sampling (size set / critical points).

■ Verification of seams,

measurements, trims, and color consistency.

■ Immediate corrections and

corrective action recording (CAPA).

This step ensures continuous quality and

prevents rework at the end.

10.

FINAL INSPECTION AND PRE-SHIPMENT REPORT (2 days)

AQL Level II Sampling - 2.5 (10 - 20% per model):

■ Measurements,

finishing, labeling, and packaging compliance.

■ Verification of boxes,

shipping marks, and quantities per size.

■ Photographic report and approval

recommendation.

The client receives a full inspection report for final approval

before shipment.

11.

EXPORT DOCUMENTS AND SHIPMENT PREPARATION (1 day)

Preparation and verification of all export and logistics

documentation:

■ Commercial Invoice, Final Packing List, Certificates of Origin

(if necessary), Test Reports.

■ Bill of Lading / Air Waybill, booking and

delivery to forwarder.

■ Consistency check between PO, Invoice, and PL.

After final approval, the shipment is released.